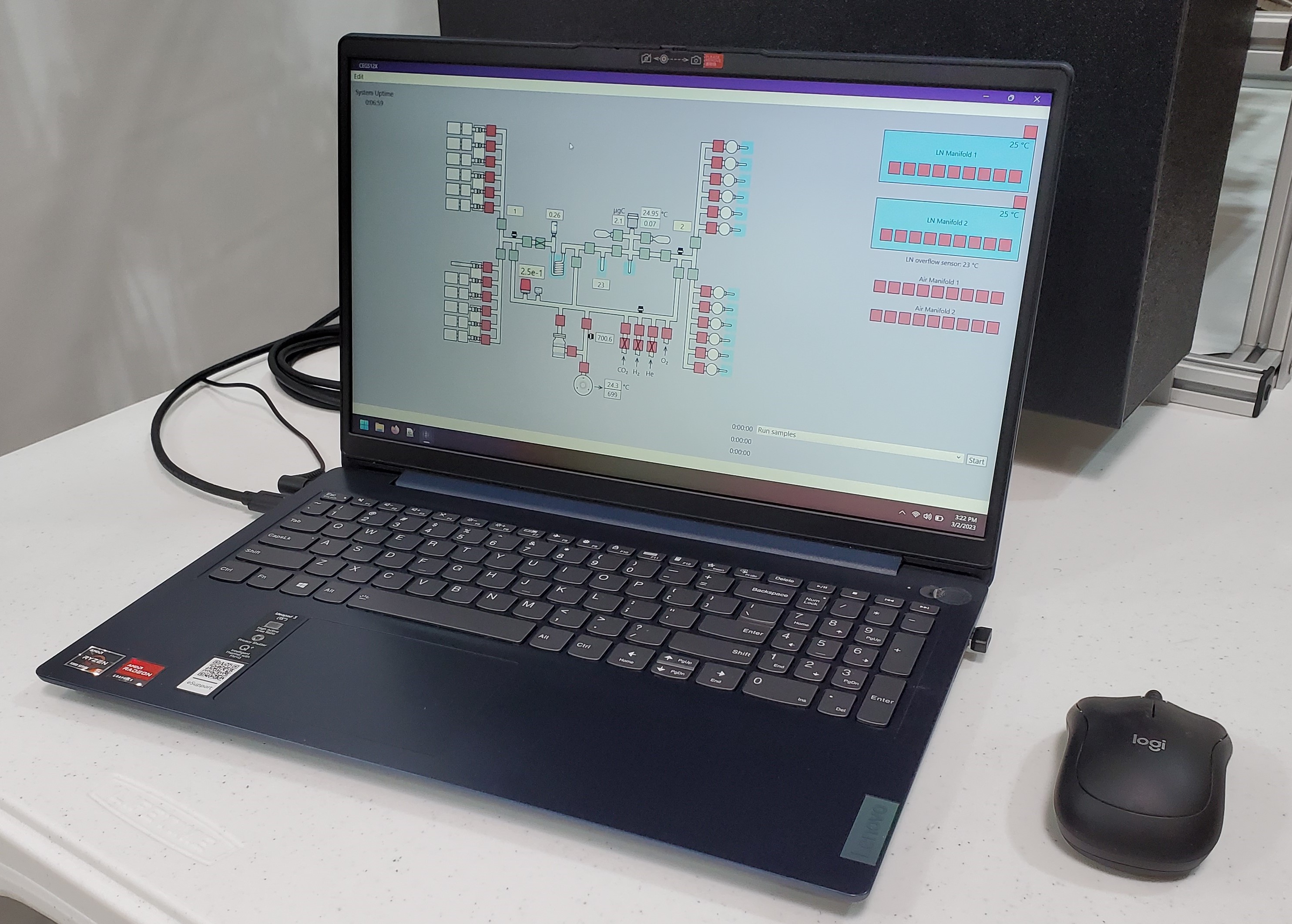

Load a pretreated sample into an inlet port, select your process from a drop-down menu, click Start, and you can walk away. The system notifies you by email or text message when it's ready for another sample.

Once the reactor bank is full of completed samples, the graphite is easily unloaded for packing into accelerator targets. After receiving new dessicant and iron catalyst, a short automatic procedure prepares the reactors for another batch of samples. Total human effort averages less than 5 minutes per sample.

Quick-change inlet port adapters allow the CEGS to easily accept organic, carbonate, and gas samples. Stepped-temperature combustion is built-in. Any fraction can be analyzed or discarded independently of the others.

A column of hot quartz media, loaded directly into the combustion tube, ensures that all carbon is fully oxidized. A 20-micron frit and a 10-micron stainless steel screen prevent particulate intrusion into the vacuum system. The fan-cooled stainless steel trap immediately above the combustion chamber captures room-temperature condensable combustion gas products. These measures work to keep the inlet port and the rest of the vacuum system clean for years of service.

The Process Section's task is "quantitative purification." It captures essentially all of the sample's carbon (typically > 99%) while at the same time rejecting or removing everything else.

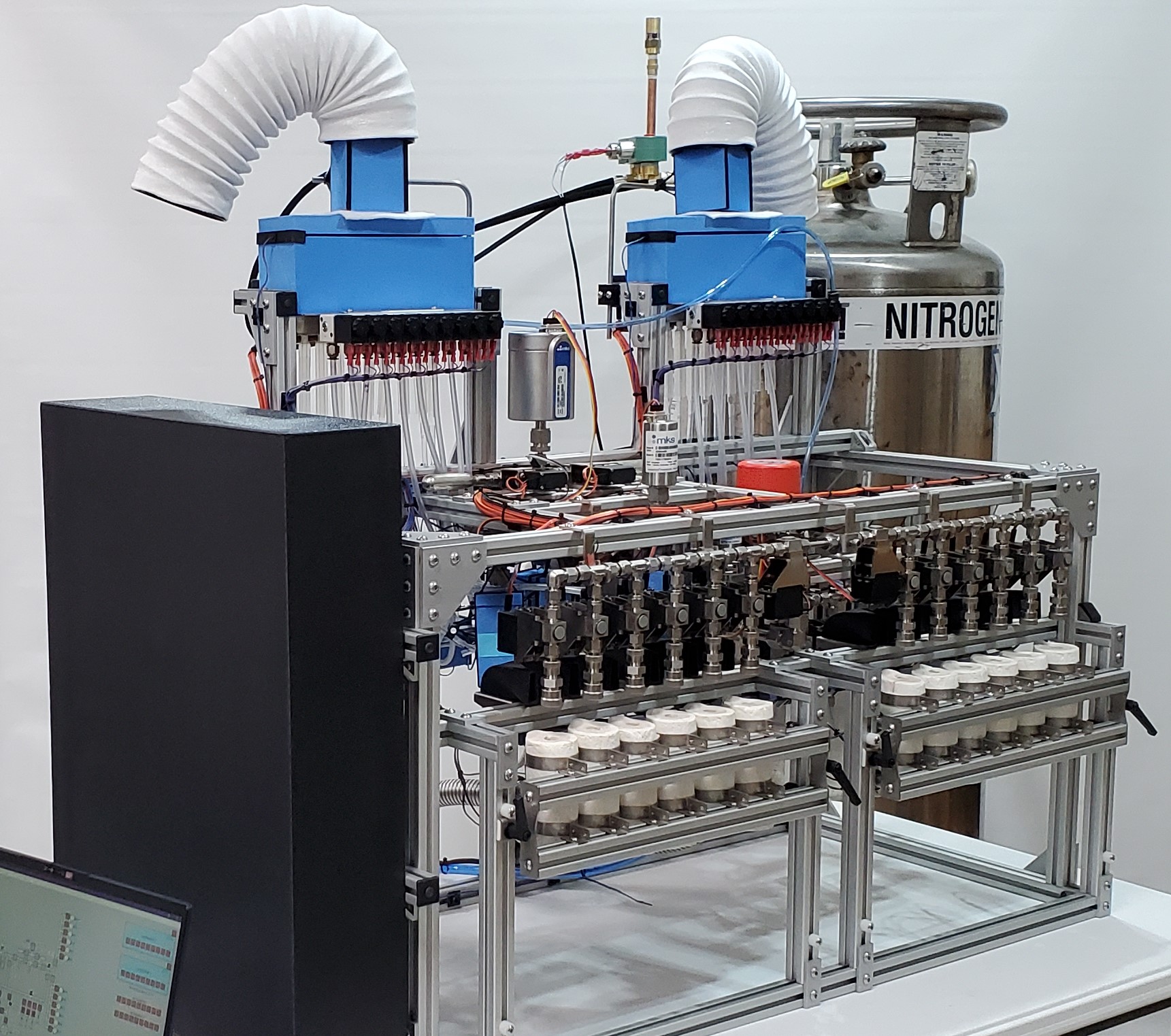

Each Aeon CEGS offers fully automated process control, with stepped combustion, carbon dioxide collection, purification, measurement and reduction to graphite integrated into a single, seamless process.

The operator simply loads the samples into the configurable inlet ports and enters the sample data into the system computer, selecting the desired process for each sample. Once the "Start" button is clicked, the system automatically executes the selected process for each sample in sequence, and notifies the operator by text or email when the run is complete.

The CEGS 12X is capable of processing twelve organic samples in a 24-hour period. Throughput for digested carbonates and gas samples can be higher, potentially up to 24, depending on sample sizes, process selection, and operator availability.

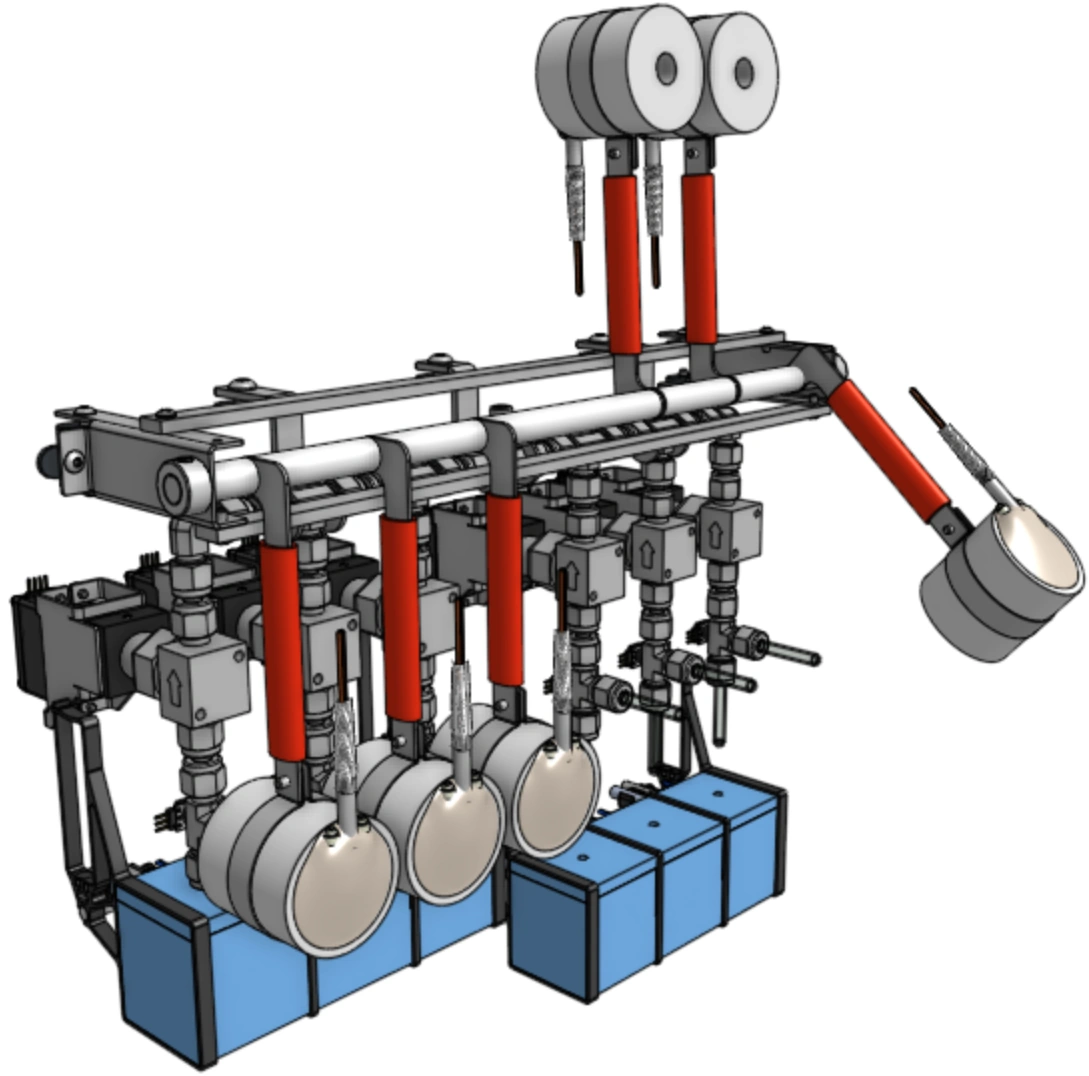

The sample enters the Process Section as a mixture of gases from an inlet port. The coil trap collects the condensable gases from the mixture, while allowing the incondensable gases to be evacuated away. The collected condensables are then transferred to the variable temperature coldfinger, which sublimes only the carbon dioxide (CO2) into the Measurement Chamber, where it is quantified.

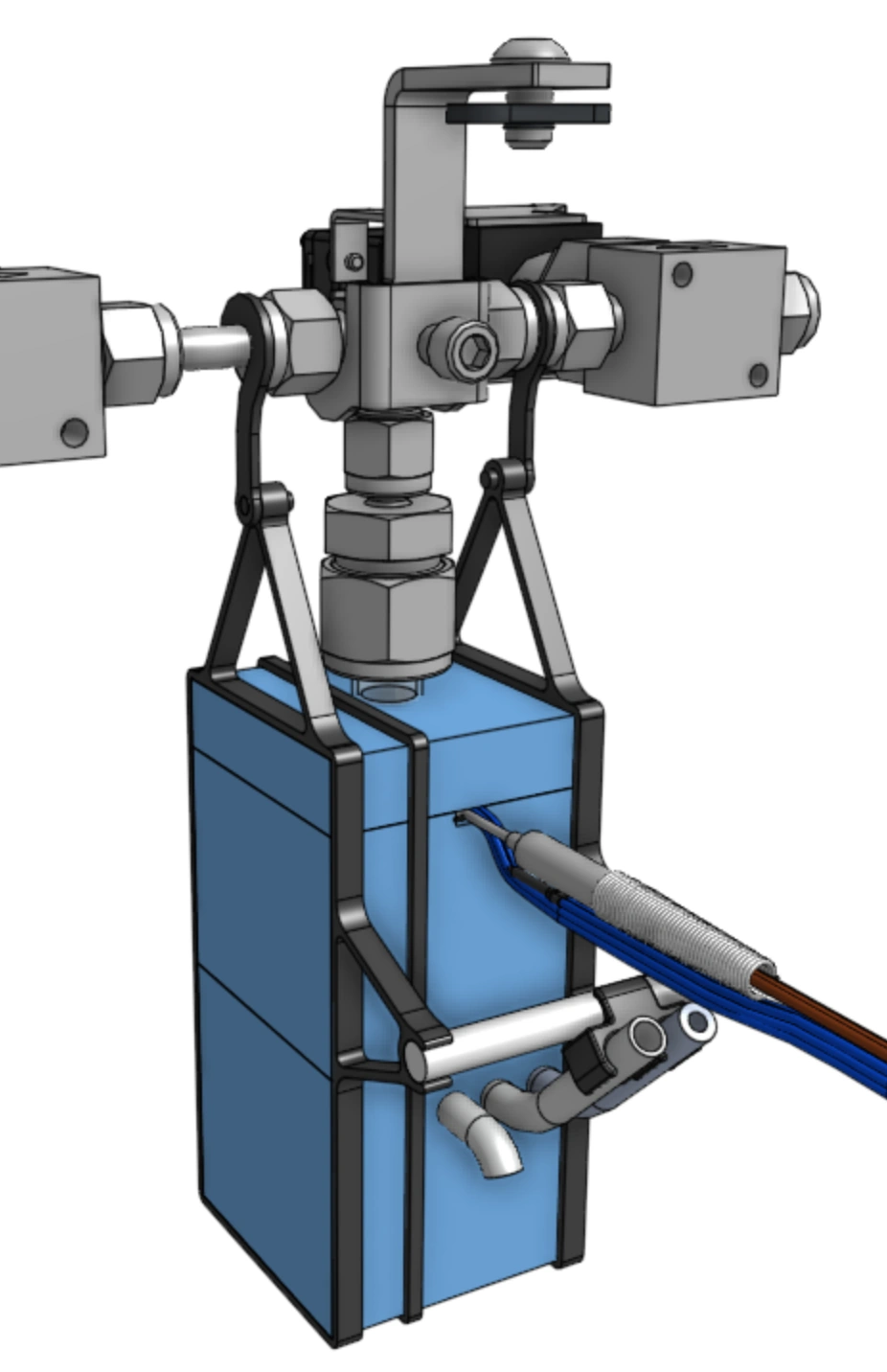

Throughout the CEGS, "Freeze-Thaw" coldfingers (FTCs) use liquid nitrogen to transfer gases from chamber to chamber. The FTCs are managed by a reliable, efficient liquid nitrogen and compressed-air delivery system. FTCs have two stable temperatures: When liquid nitrogen is present, they are frozen at -196 °C, and when it is not, they are thawed at approximately room temperature.

Aeon's variable-temperature coldfinger (VTC) is unique in that its temperature can be controlled and held stable in 1-°C increments over its entire operating range of approximately -190 to 50 °C. Its controller provides excellent precision and stability, which enables the quantitative isolation of specific gases by their distinctive phase change properties.

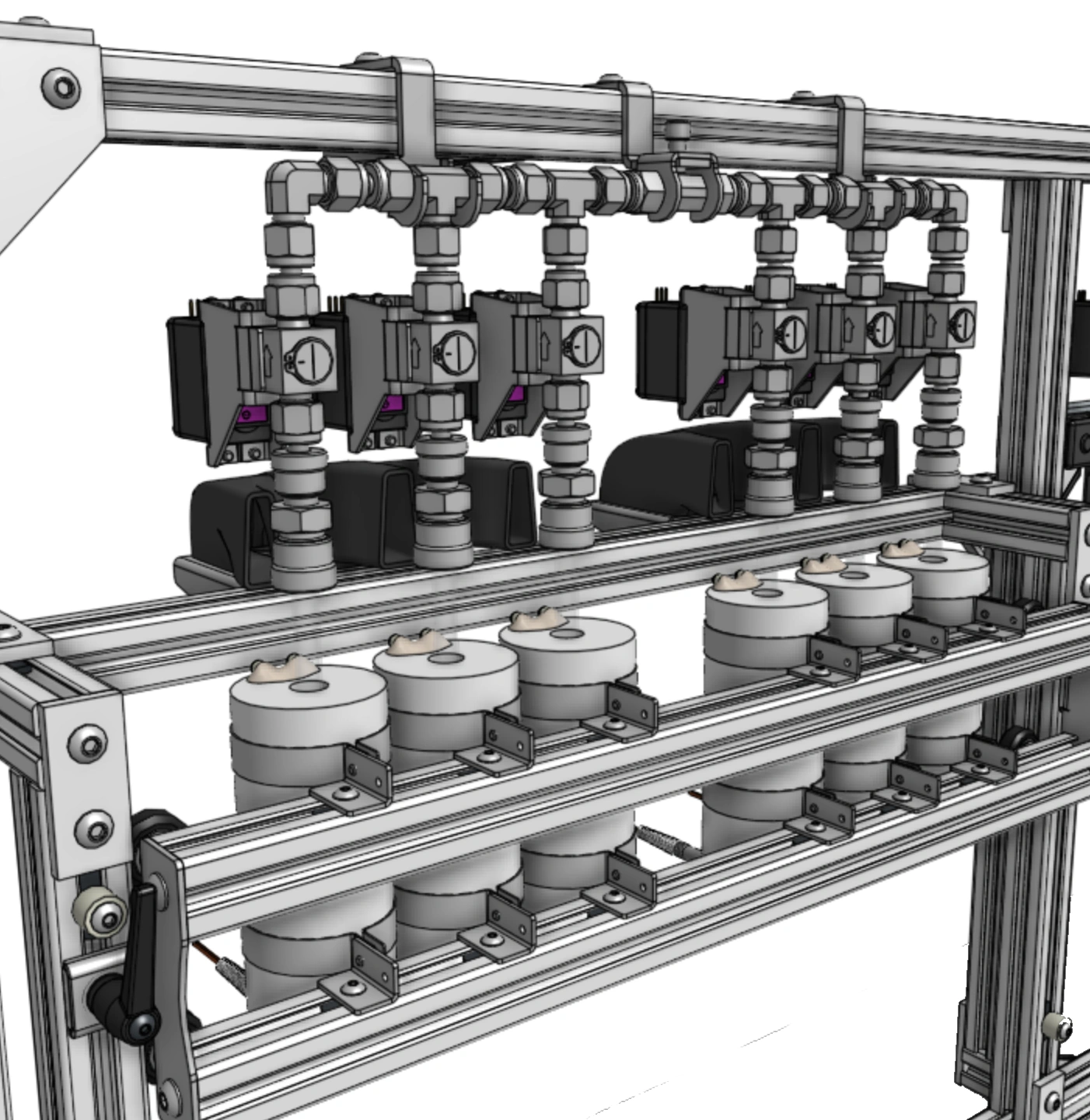

The Measurement Chamber forwards the pure, quantified sample CO2, or an aliquot of it, to one of the graphite reactors for reduction. Here the gas is converted to solid carbon, "graphite", using hydrogen and iron powder as a catalyst. Once the CO2 and hydrogen are received, each graphite reactor operates autonomously. This permits the system to carry on processing other samples, while the reduction takes place.

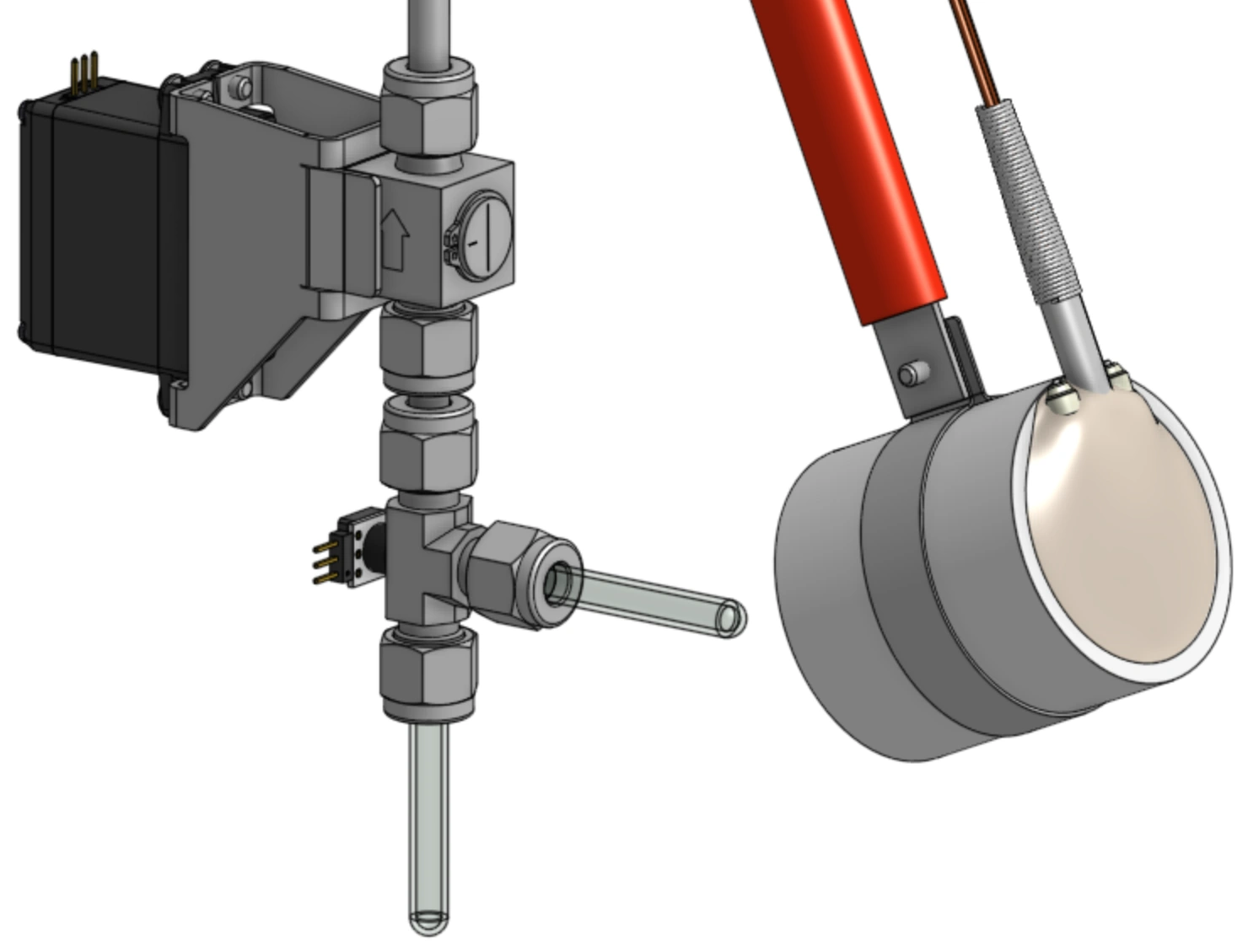

A small amount of iron powder in the tip of the horizontal culture tube is heated by the reactor furnace lowered over it. Magnesium perchlorate chips placed in the bottom of the vertical culture tube absorb the water produced by the reduction reactions. A tiny pressure sensor in the back of the tee monitors reaction progress. The vertical "perchlorate" tube also functions as a coldfinger, to transfer the CO2 into the reactor (FTC not shown). The reactor furnace is raised and the FTC lowered to provide service access, as fresh tubes, iron, perchlorate, and O-rings are needed for each sample.

.webp)

Every radiocarbon lab is unique. So, Aeon's CEGS are available in numerous configurations. A smaller lab with modest throughput might prefer the original CEGS 6x1, which features six graphite reactors and one inlet port.

The CEGS 6X, with 6 graphite reactors and 6 inlet ports, provides a mid-range solution that reduces the frequency of operator visits.

.webp)

A large facility needing to process up to 24 organic samples per day might opt for the CEGS 12X, with its 12 graphite reactors and 12 inlet ports.

A researcher that frequently analyzes very old (> 35 ka) or small (< 50 μg C) samples will prefer a low-level (LL) system. The low-level option features all metal-sealed valves in the sample path, vastly reducing the amount of Viton in the system. The minimized gas loads from permeation and outgassing permit quantitative handling of samples as tiny as 5 micrograms of carbon.

.webp)

Some sample types require specialized carbon liberation processes. Examples include DIC water, DOC water, and cosmogenic samples. In such cases, a CEGS can be integrated onto the end of the lab's specialized carbon liberation equipment, to purify, quanitify and graphitize the samples as they arrive.

Aeon's open-source HACS framework enables you to fully automate your existing specialized CO2 production system, and integrate it seamlessly into your CEGS application. Or perhaps your existing system is already automated, using LabVIEW, for example. In cases like this, a very simple text file protocol can hand off the liberated CO2 sample to your CEGS. The two systems can be networked, or often, both systems can run side-by-side on the same host computer.

| Key features | |

|

|

| Performance specifications | |

|

|

| Every Aeon CEGS purchase includes | |

|

|

| The Aeon CEGS requires the following | |

|

|

| Limited Warranty |

|

Aeon Laboratories, LLC, ("Aeon") warrants that its products will be free of defects in material and workmanship for a period of one year from the date of installation by Aeon, or from the date of delivery if installation is done by a party other than Aeon ("Warranty Period"). If a defect arises during the Warranty Period, the original purchaser may return the defective component to Aeon for repair or replacement, at Aeon's option. This limited warranty does not cover damage caused by misuse, abuse, accident, neglect, or modification of the product. This limited warranty is the sole and exclusive remedy, and liability of Aeon with respect to any defect in its products. Aeon shall not be liable for any incidental or consequential damages, including but not limited to lost profits, lost revenue, or loss of use, even if Aeon has been advised of the possibility of such damages. This limited warranty is in lieu of all other warranties, express or implied, including but not limited to the implied warranties of merchantability and fitness for a particular purpose. Some states or jurisdictions do not allow limitations on how long an implied warranty lasts or the exclusion or limitation of incidental or consequential damages, so the above limitations or exclusions may not apply to you. This limited warranty gives you specific legal rights, and you may also have other rights which vary from state to state or jurisdiction to jurisdiction. |